Brazering Ring Uses: The Comprehensive Guide

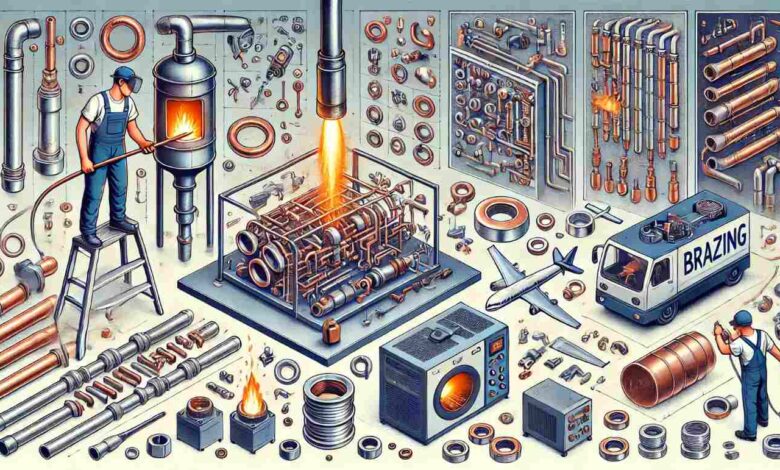

Brazering is a versatile metal-joining process that has been employed across various industries for decades. One of its key components is the brazing ring, a preformed piece that facilitates the joining of metal surfaces using a filler material. In this guide, we’ll explore the uses and advantages of brazing rings, providing a comprehensive overview of their role in the brazing process.

What is Brazing?

Brazing is a technique to join two or more metals with the help of a molten alloy [filler metal], which has a lower melting point than the workpieces. Whereas welding is a process that melts the parent metals, brazing takes place at much lower temperatures, typically above 450°C (842°F), yet below the melting point of the parent metals. This maintains the mechanical properties of the base materials, making it ideal for welding dissimilar metals together.

The Role of Brazing Rings

A brazing ring is a form of filler metal in a circular shape that can either go around the joint or inside it. They simplify the brazing process by ensuring the right amount of filler material is present, leading to stronger, more consistent joints. These rings are built from copper, silver, and aluminum and can be customized to meet the needs of specific applications.

Advantages of Using Brazing Rings

Reliable and Repeatability: Brazing rings feed an exact quantity of filler material, ensuring joint consistency. This prevents overfilling, which is when excessive filler material is used, creating additional wasted product and higher costs.

Better Joint Quality: Brazing rings are preformed and therefore, the joint configuration offers enhanced control. This can result in cleaner and stiffer joints with fewer gaps than you generally get with other types of joining.

Applicable to a Wide Range of Materials: Brazing rings are compatible with copper, brass, and aluminum as well as some types of steel. This versatility makes them perfect for many different applications, including plumbing and aerospace.

Operator skill can be minimized: Brazing rings require less skilled operators to make up the joints as their preparations and setups are made easy. Which is especially useful in a production environment.

Types of Brazing Processes Involving Rings

1. Torch Brazing

Torch brazing is also widely used for limited production runs or custom applications. Here, the operator lights a gas flame and heats the base metals together with the brazing ring until they reach a high enough temperature to flow the filler metal into the joint by capillary action as shown in Fig 1. It is considered as a flexible and user-friendly technique.

2. Furnace Brazing

This is particularly beneficial for mass production because it permits many joints to be brazed simultaneously under controlled conditions. In that process, the assemblies are placed in a furnace and brazing rings are used to control how much filler is applied at different joints.

3. Induction Brazing

Induction brazing is a process where two or more materials (usually metals) are joined together using a filler metal that has a lower melting temperature than the workpiece in question. It is a fast-working method and heating timings are often reduced. In addition, brazering rings can be added to create designed filler distribution during the induction process.

4. Dip Brazing

Dip Brazing where the assembly is immersed in a molten filler metal together. This enables intricate parts to be joined together and aids in the use of brazing rings with complex shapes.

Applications of Brazing Rings

Brazing rings find applications in various fields, including:

HVAC Systems: Used to join copper tubing and fittings, ensuring leak-proof joints that can withstand pressure.

Automotive Industry: Commonly employed in the assembly of radiators and heat exchangers, where strong and durable joints are crucial.

Aerospace: Utilized for joining components where weight and strength are critical, such as in aircraft frames and engine assemblies.

Plumbing: Essential for creating reliable connections in piping systems, ensuring durability and resistance to thermal expansion.

The Bottom Line

In the brazering process, brazing rings play an important role by improving joint quality and making operations more convenient. Due to their benefits in terms of uniformity, flexibility, and ease of use, they are widely applied in various industries. As technology advances, brazering methods and applications are expected to modernize further, solidifying it as a key process in metalworking and manufacturing.