The Ultimate Guide to Diamond Touch Innovations

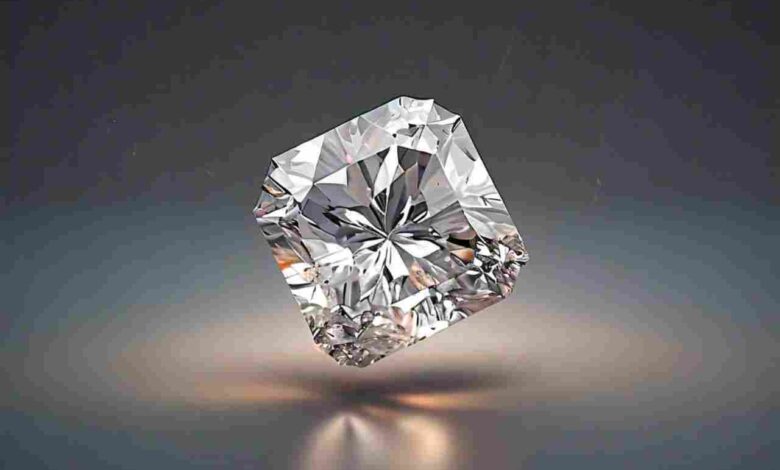

When it comes to the forefront of technological advances and industrial progression, Diamonds Touch Innovations prides themselves in leadership. Whether you consider the development of artificial synthetic diamonds or state-of-the-art abrasive materials, Diamond Innovations has played a major role. Everything you ever wanted to know about diamond touch innovations.

The History of Diamond Innovations

Founded in 1957, Diamond Innovations has a long and storied history. The company was founded when De Beers decided to build its own research facility in order to investigate the potential industrial applications for synthetic diamonds – a product that had formerly been limited mainly by low quality and an occasional lack of consistency. Through various mergers and acquisitions over the years, Diamond Innovations eventually became a part of Sandvik Hyperion in 2014 when Sandvik Hard Materials was restructured to form the new entity.

What Are Diamond Touch Innovations?

Diamond Touch Innovations – The innovation and implementation of synthetic diamonds & superabrasive materials. Many industries such as manufacturing, mining and even healthcare have been completely hit by these new innovations. The common denominator among these advancements, however – whether used in the exoskeleton project some future modular accessory – are synthetic diamonds and cubic boron nitride (CBN) which share an unsurpassed hardness and durability.

Innovations and Technologies

Synthetic Diamonds

Synthetic diamonds are above all produced by high-pressure, heat-intensive (HPHT) cutting processes or comparable practices that create a layer of synthetic diamond around the carbon atoms. These diamonds are used not only for cutting and grinding tools but also elsewhere in mechanical processing and scientific applications including high-precision medical devices and semiconductors.

Cubic Boron Nitride (CBN)

Another innovative material developed by Diamond Innovations is CBN. With hardness close to diamonds, second hardest substance known on earth you will understand it the ideal for grinding and cutting where extreme sharpness is required. CBN works very well in hardened steels and other tough-to-cut materials.

Advanced Coatings

Some stuff is going on transparent of IIa De Beers but classified for those applications such as coatings used in various industrial operations and the like. That means extending the life of cutting tools, which improves their durability and productivity by eliminating number or passes to finish a job. In high-wear environments like mining and metalworking this is a major win.

Applications of Diamond Touch Innovations

Industrial Manufacturing

For example, the efficiency and accuracy of machining processes in manufacturing have been considerably improved by Diamond Touch Innovations. They are ideal for the machining of hard metals, ceramics and composites in very demanding applications were excellent surface finishes can not be achieved by standard tooling – used both to machine these materials but also as wear protection parts.

Healthcare

The healthcare industry diamond tools and devices. They include processes which allow for ultra-sharp surgical devices and robust medical implants. Synthetic diamonds, known for accuracy and non-toxicity, are ideal for long-lasting, durable surgical implants.

Electronics

Synthetic diamonds are used to produce semiconductors and high performance electronic devices in the electronics field. Especially the heat-conduction and electrical characteristics of diamond makes it possible to produce faster electronic components

The Manufacturing Process of Synthetic Diamonds

There are two main methods for the production of synthetic diamonds: High Pressure, High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

High Pressure High Temperature (HPHT)

The HPHT process is designed to duplicate the environment in which diamonds are formed within Earth. This process includes high-pressure, high-temperature treatment of carbon-to-diamonds. HPHT is largely used for manufacturing industrial-grade diamonds that are further employed in numerous abrasives and cutting tools.

Chemical Vapor Deposition (CVD)

Whereas CVD consists in exposing a substrate to carbon-rich gases into an enclosed chamber. Carbon atoms are deposited on the appropriate substrate to make a diamond layer, and from this point, they can be energized with gases. This method, with better property control, suits both industrial uses and high-quality gem production.

Future Trends in Diamond Touch Innovations

Watch the video for more on Diamond Touch Innovations: Future Trends in Diamond Touch Innovations The future of Diamon Touch is bright with continuous research directed at increasing the usage and production efficiency of synthetic diamond and CBN materials. Possible advances include new composite materials and coating techniques that could catalyze further industry disruption.

The Impact of Diamond Touch Innovations on Sustainability

Synthetic diamonds are a much greener alternative and have strong environmental benefits. Synthetic diamonds are lab-made, avoiding the costly and polluting process of traditional mining. Because these diamond-coated tools also last longer, you have fewer replacements and therefore less industrial waste as well.